Fill & Finish

All of our production takes place on site and under one roof from a single provider.

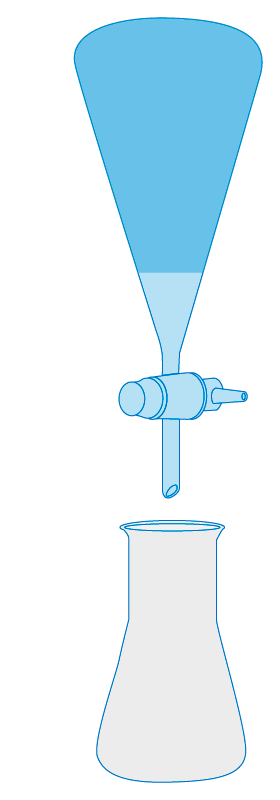

Pharmpur specializes in producing liquid medicinal and medical products in syringes and vials. The production usually comprises the following steps:

Pharmpur specializes in producing liquid medicinal and medical products in syringes and vials. The production usually comprises the following steps:

The Fill & Finish processes making highly-viscous media is one of Pharmpur’s specialties. It comprises the production of homogeneous preparations, low-loss product handling, and an air bubble-free filling in syringes by filling and closure processes occurring under a vacuum.

Pharmpur possesses a manufacturing licence for the production of small-volume investigational medicinal products that are sterilised in final containers and intended for human use in liquid form. This comprises entire or partial production entailing various related processes such as packing and labelling.

Pharmpur conducts research and development to synthesise new materials, bond known substances to substrate materials and produce supplementary and new materials for medical use which primarily comprises the hydrogel class of substances. These procedures include tailor-made purification processes. The projects are self-financed, as a commission order or within the framework of funded research collaborations.

Innovative concepts are realised via interdisciplinary collaborations and brought to product maturity. Examples thereof are currently-sponsored projects. A highly motivated team of staff members with outstanding professional qualifications – including six PhD chemists – guarantee pragmatic and rapid completion of projects.

Laser for cataract surgery; project management: VDI. A current project in cooperation with

LED for ocular illumination; project management: AiF. A current project in cooperation with:

Idea Finding

We determine the need for new products by active consultation with their users. Novel concepts emerge by seeking solutions to problems – and these ideas eventually lead to jointly-created project proposals.

Business Development Phase

If the prototypes satisfy the project’s specific requirements, the samples are subjected to testing in the market. The subsequent procedure depends closely on the dialogue with users and consideration of proposals for improvements.

Market Readiness

While waiting for product approval, distribution paths are identified through business networks and in close contact with opinion leaders in the industry before deciding on the ultimate version of the product.

The synthesis and purification of raw materials for the Fill & Finish processes are implemented in our own laboratories on the kilo scale. Purification is tailored to the impurity profile resulting from the production process. The success of synthesis and purification is continuously monitored by multiple specific analyses.

The Analytics business unit is integrated within the branches of quality control, stability testing, product care, and research and development.

With a dense network of controls, our production processes are monitored in each batch. Within the course of the batch release, the specified values are characterized. The results are summarized in certificates of analysis. These works are carried out in our in-house laboratories by highly qualified staff members.

Pharmpur specialises in the comprehensive production of ocular endotamponades and ophthalmological preparations with focus on silicone materials, fluororganic compounds and viscoelastic substances. All analytic methods are backed by validations and are guaranteed GMP-compliant.